Detoxifying exhaust gas from device production processes

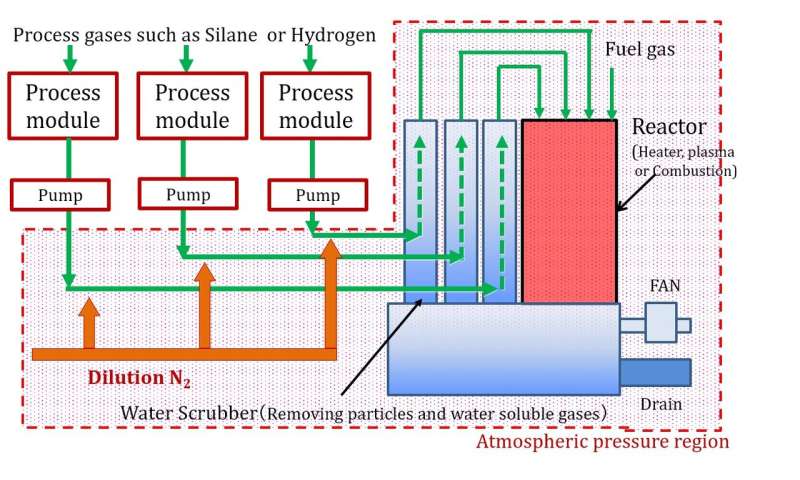

Manufacturing process for industries of electronics, such as semiconductors, flat panel displays, and solar batteries uses dangerous toxic and flammable gases, such as silane gas and hydrogen gas. Currently, to detoxify these dangerous gases, a thermal oxidation reaction, in which they are heated to 1000℃ or more and decomposed is mainly used. For example, as silane gas, which is often used in the chemical vapor disposition (CVD) process for semiconductors, causes an explosive reaction when it comes into contact with the air, after diluting the concentration with large amounts of nitrogen gas so that the concentration is below the lower explosion limit, it can be heat-treated and detoxified. Previously, the development of reacting furnace structures was limited to improving the efficiency of heating means and reducing wasted energy, such as heat dissipation, so the development of a drastic technology that can realize energy savings has become an important issue.

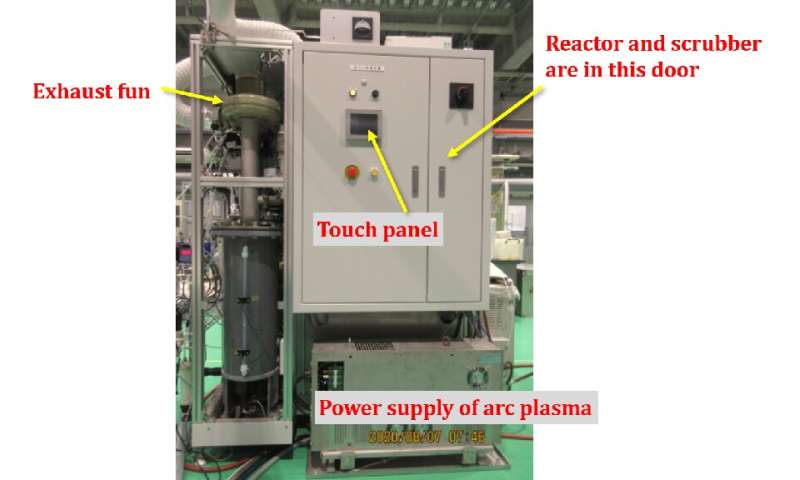

In the JST Adaptable and Seamless Technology Transfer Program through Target-driven R&D (A-STEP), corporate development for detoxifying dangerous gases with high efficiency and low energy has been entrusted to Kanken Techno Co. Ltd, based on the results of the research by Professor Takanori Ichiki of the Graduate School of Engineering, the University of Tokyo.

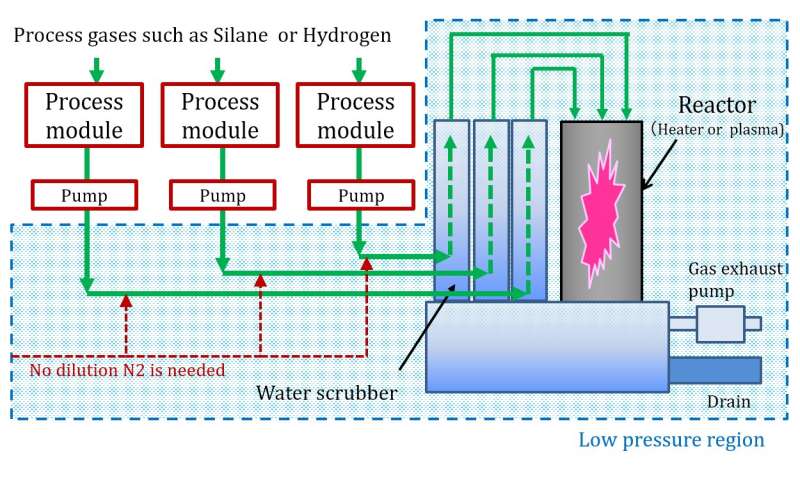

The development team has focused on the fact that the lower explosion limit depends on pressure of flammable gases and examined the pressure conditions at which the amount of dilution gases can be reduced. Reducing the pressure within the pipe from the pump outlet of the device manufacturing equipment to the exhaust gas abatement device, they created an environment in which the lower explosion limit was increased and no chemical reaction was caused. Additionally, as the heat source for breaking down exhaust gases, they discovered the optimal conditions for stably generating arc plasma, which is normally generated in atmospheric pressure, in a reduced pressure state of approximately 0.1 to 10 kPa. In this way, they made it possible to perform detoxification processing by thermally reacting the dangerous gas with oxygen, using the arc plasma heat source, within an exhaust gas abatement device in a reduced pressure state. Since dilution with large quantities of nitrogen gas is unnecessary with the CVD process, the amount of energy required for exhaust gas processing has been successfully reduced by up to 75% when processing silane gas.

The developed abatement system can be simply applied to exhaust gases containing flammable gases requiring nitrogen gas dilution other than silane gas by optimizing the processing conditions, without changing the device structure. This promises to find applications in manufacturing devices using hydrogen gases, such as the hydrogen processing of silicon wafers, epitaxial growth, and ashing of organic films.

Provided by Japan Science and Technology Agency (JST)